Water treatment facilities are the backbone of public health infrastructure, processing millions of gallons daily to ensure safe drinking water for communities across America. Traditional inspection methods for these complex facilities often involve significant safety risks, operational downtime, and substantial costs. Enter drone technology—a game-changing solution that’s transforming how water treatment plants approach facility inspections, maintenance planning, and operational efficiency.

The Challenge of Traditional Water Treatment Plant Inspections

Water treatment facilities present unique inspection challenges that have persisted for decades. Plant operators must regularly assess massive clarifiers, sedimentation basins, filtration systems, and elevated storage tanks—often requiring scaffolding, rope access, or specialized equipment that can cost thousands of dollars per inspection.

Traditional inspection methods pose several critical limitations. Safety concerns top the list, as inspectors must navigate confined spaces, work at dangerous heights, and potentially expose themselves to hazardous chemicals. The time-intensive nature of manual inspections often requires partial shutdowns or operational modifications, directly impacting water production capacity. Additionally, accessibility issues mean some areas receive less frequent inspection attention, potentially allowing problems to develop undetected.

The financial impact is equally significant. Manual inspections require specialized personnel, expensive access equipment, and extended operational disruptions. A single comprehensive facility inspection can cost upwards of $50,000 when accounting for labor, equipment rental, and lost production time.

How Drones Transform Water Treatment Facility Operations

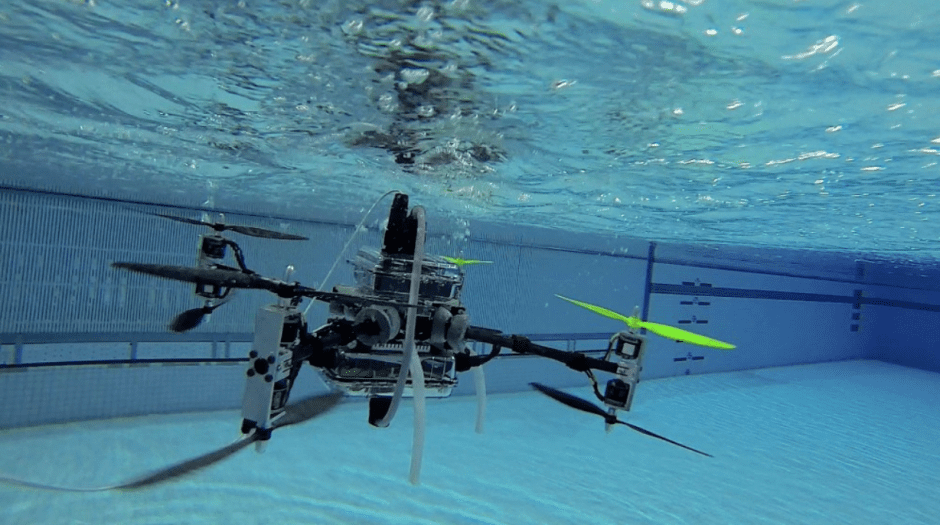

Drone technology addresses these challenges with unprecedented efficiency and safety improvements. Unmanned aerial systems can access virtually any area of a water treatment facility without requiring scaffolding, confined space entry, or operational shutdowns. This capability alone represents a paradigm shift in how facilities approach routine maintenance and emergency response situations.

Modern drones equipped with high-resolution cameras, thermal imaging sensors, and specialized payloads can detect issues that might be missed during traditional inspections. Thermal cameras identify temperature variations that indicate equipment malfunctions or energy inefficiencies. High-resolution visual cameras capture detailed imagery of structural components, allowing for precise documentation and analysis. Some advanced systems even incorporate gas detection sensors to monitor air quality around chemical storage areas.

The speed advantage is remarkable. What once required days of preparation and execution can now be completed in hours. A comprehensive drone inspection of a major water treatment facility typically takes 2-4 hours compared to 2-3 days for traditional methods. This efficiency translates directly to cost savings and improved operational continuity.

Data collection capabilities represent another significant advantage. Drone inspections generate comprehensive digital records, including georeferenced imagery, thermal maps, and detailed video documentation. This data becomes invaluable for maintenance planning, regulatory compliance, and long-term facility management decisions.

Essential Skills for Water Treatment Drone Operations

Operating drones in water treatment environments requires specialized knowledge beyond basic FAA Part 107 certification. Pilots must understand the unique operational challenges these facilities present, including restricted airspace considerations, chemical safety protocols, and environmental regulations that govern water infrastructure.

Understanding water treatment processes is fundamental. Drone pilots working in these environments need familiarity with clarifier operations, sedimentation basin dynamics, and filtration system components. This knowledge enables more effective flight planning and helps pilots identify potential issues during inspections.

Flight planning skills become critical when working around complex infrastructure. Water treatment plants feature numerous obstacles including towers, pipes, electrical systems, and restricted areas. Successful drone operations require careful pre-flight planning to ensure comprehensive coverage while maintaining safe distances from critical equipment.

Environmental awareness is equally important. Weather conditions can significantly impact both drone performance and water treatment operations. Pilots must understand how wind patterns around large structures affect flight stability and how environmental factors like humidity and temperature influence equipment performance.

Data management and analysis capabilities distinguish professional operators from hobbyists. Water treatment facility inspections generate substantial amounts of visual and thermal data that must be organized, analyzed, and presented in actionable formats for facility managers and maintenance teams.

Advanced Applications in Water Infrastructure

The versatility of drone technology extends far beyond basic visual inspections. Advanced applications are revolutionizing how water treatment facilities approach everything from routine maintenance to emergency response.

Thermal imaging applications provide invaluable insights into equipment performance and energy efficiency. Thermal cameras can identify hot spots in electrical systems, detect insulation failures in buildings, and monitor temperature variations in treatment processes. These capabilities enable predictive maintenance strategies that prevent equipment failures before they occur.

Structural analysis applications utilize high-resolution imagery and photogrammetry to create detailed 3D models of facility components. These models enable precise measurements, change detection over time, and detailed structural assessments without requiring physical access to elevated or dangerous areas.

Environmental monitoring capabilities include air quality assessment around chemical storage areas, water quality monitoring using specialized sensors, and vegetation management around facility perimeters. Some advanced systems can even detect gas leaks or chemical spills that might pose environmental risks.

Emergency response applications prove particularly valuable during natural disasters or equipment failures. Drones can quickly assess damage, identify safety hazards, and help coordinate repair efforts without exposing personnel to dangerous conditions.

Regulatory Compliance and Safety Protocols

Water treatment drone operations must navigate complex regulatory environments that include FAA regulations, environmental protection requirements, and water quality standards. Understanding these regulatory frameworks is essential for successful program implementation.

FAA Part 107 certification provides the foundation, but water treatment operations often require additional considerations. Many facilities are located near airports or in controlled airspace, requiring coordination with air traffic control. Some operations may require beyond visual line of sight (BVLOS) waivers for comprehensive facility coverage.

Environmental regulations add another layer of complexity. Operations near water bodies may fall under EPA oversight, and flights over treatment processes must consider potential contamination risks. Drone pilots must understand how their operations might impact water quality or treatment processes.

Safety protocols extend beyond standard drone operations. Chemical safety awareness becomes critical when operating around chlorine storage, chemical feed systems, and wastewater treatment areas. Pilots must understand facility emergency procedures and coordinate with plant operators to ensure safe operations.

Documentation requirements for water infrastructure inspections often exceed those for other industries. Regulatory compliance may require specific data formats, inspection frequencies, and reporting protocols that drone programs must accommodate.

Implementation Strategies for Water Treatment Facilities

Successful drone program implementation requires careful planning and stakeholder buy-in. Facilities must consider operational integration, staff training requirements, equipment selection, and performance measurement strategies.

Operational integration begins with identifying specific use cases where drone technology provides the greatest value. Most facilities start with routine visual inspections of elevated structures before expanding to thermal imaging and specialized applications. This phased approach allows staff to develop expertise while demonstrating program value.

Staff training considerations include both drone pilot certification and facility-specific knowledge transfer. Existing maintenance staff often make excellent drone pilots because they already understand facility operations and can identify potential issues during flights. However, comprehensive training programs must address both technical drone operation and facility-specific safety protocols.

Equipment selection depends on specific facility requirements and budget constraints. Entry-level programs might start with standard visual inspection capabilities, while advanced implementations incorporate thermal imaging, gas detection, and specialized sensors. Facilities must balance capability requirements with budget constraints and operational complexity.

Performance measurement strategies help demonstrate program value and guide future investments. Key metrics typically include inspection cost reductions, safety incident prevention, maintenance efficiency improvements, and regulatory compliance enhancements.

ROI Analysis: The Business Case for Drone Integration

The financial benefits of drone integration in water treatment operations are substantial and measurable. Understanding these benefits helps facility managers build compelling business cases for program investment.

Direct cost savings come from reduced inspection expenses, eliminated equipment rental costs, and decreased labor requirements. A facility spending $200,000 annually on traditional inspections might reduce those costs by 60-70% through drone implementation, generating immediate savings of $120,000-$140,000 per year.

Safety improvements provide additional value through reduced insurance costs and eliminated safety incidents. The average workplace injury in water treatment facilities costs approximately $45,000 in direct and indirect expenses. Preventing just three injuries per year through improved safety protocols justifies significant drone program investments.

Operational efficiency gains include reduced downtime, improved maintenance planning, and enhanced emergency response capabilities. These benefits are often difficult to quantify precisely but can represent substantial value through improved service reliability and customer satisfaction.

Long-term strategic advantages include improved regulatory compliance, enhanced data collection capabilities, and positioning for future technology adoption. These benefits compound over time and provide ongoing competitive advantages.

Training Programs and Certification Pathways

Professional drone training for water treatment applications requires specialized curricula that address both technical drone operation and industry-specific requirements. Comprehensive training programs combine classroom instruction, hands-on flight training, and facility-specific operational procedures.

Foundational training begins with FAA Part 107 certification, covering airspace regulations, weather considerations, and basic flight operations. This certification provides the legal foundation for commercial drone operations but represents only the beginning of professional competency development.

Industry-specific training addresses water treatment facility operations, safety protocols, and specialized inspection techniques. Participants learn to identify common infrastructure issues, understand treatment process implications, and develop effective flight planning strategies for complex environments.

Advanced certification pathways include thermal imaging interpretation, photogrammetry applications, and specialized sensor operations. These capabilities enable more sophisticated inspection and analysis services that provide greater value to facility operations.

Ongoing education requirements ensure pilots maintain current knowledge of evolving regulations, technology developments, and industry best practices. Professional development programs help drone pilots advance their careers while providing facilities with increasingly sophisticated capabilities.

Ready to transform your water treatment facility’s inspection capabilities? Drone Universities offers specialized training programs designed specifically for infrastructure professionals, combining FAA-certified instruction with industry expertise to prepare your team for the future of facility management.

Conclusion: The Future of Water Treatment Inspections

Drone technology represents a fundamental shift in how water treatment facilities approach inspection, maintenance, and operational management. The benefits extend far beyond simple cost savings to include improved safety, enhanced data collection, and strategic operational advantages that position facilities for long-term success.

As technology continues advancing, we can expect even more sophisticated capabilities including artificial intelligence-powered analysis, autonomous inspection systems, and integrated facility management platforms. Facilities that invest in drone programs today position themselves at the forefront of this technological revolution.

The question isn’t whether drone technology will transform water treatment operations—it’s whether your facility will be a leader or follower in adopting these game-changing capabilities. The time to act is now, and the benefits are too significant to ignore.

Contact Drone Universities today to learn how our comprehensive training programs can prepare your team to leverage drone technology for safer, more efficient, and more cost-effective water treatment facility operations.